Solution

The company has the demand customer for each to provide the omni-directional

"one-stop" work style service.

When used with domestic wastewater, MBR processes can produce effluent of high quality enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Other advantages of MBRs over conventional processes include small footprint, easy retrofit and upgrade of old wastewater treatment plants.

Membrane technologies for municipal wastewater treatment, particularly MBRs, have been considered a reliable option for applications requiring a smaller footprint and/or higher effluent quality. In most cases of domestic wastewater treatment in developed urban areas, carbon (usually indicated by biochemical oxygen demand [BOD]) and nitrogen (NH4-N and total nitrogen (TN)) removal are achieved using biological aerobic (BOD oxidation and nitrification) and anoxic treatment (denitrification) as part of the ASP. The conventional activated sludge process (CASP) is normally designed and operated at a mixed liquor suspended solids (MLSS) concentration of less than 4 g/L and a lower range of solids retention times (SRTs) to maintain the MLSS. In MBRs, however, the typical MLSS range between 8 and 15 g/L allows the intensification of microbial suspended growth and raises the possibility of reusing existing units to increase the plant's capacity with little or no increase in the footprint. In general, an advantage of membrane technology is the capital costs of construction/installation, which are similar to or lower than those of conventional technologies;

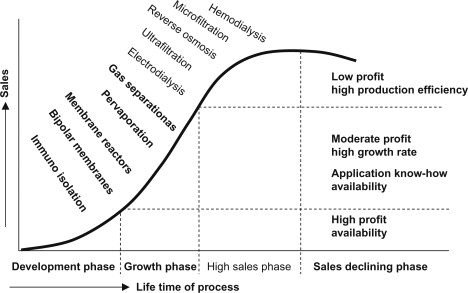

Today, membrane technology has a unique place in many industrial and water management applications. Some of those are well settled (i.e., preconcentration steps and protein fractionation in the dairy industry, municipal waste water treatment by membrane bioreactors, etc.).

When used with domestic wastewater, MBR processes can produce effluent of high quality enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Other advantages of MBRs over conventional processes include small footprint, easy retrofit and upgrade of old wastewater treatment plants.

The membrane lifetime picture has remained quite stable in the past decade, as shown in below Figure From a global perspective of the industrial-scale processes, membranes have succeeded in being alternate technologies to conventional separation techniques, Membranes can be fitted in at various places in a production facility, and they can even been synergistically combined with other separation or reaction processes leading to hybrid technologies. This is one of the powerful features of this technology.